VARAD PROCESS EQUIPMENT AND SYSTEMS

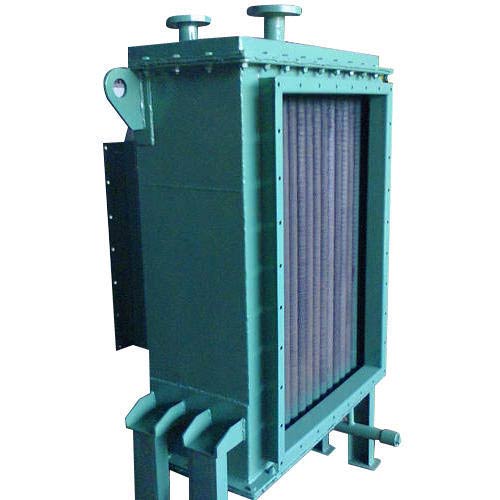

STEAM AIR HEATERS

Steam Air Heaters: Efficient Solutions for Industrial Heating

When it comes to industrial heating systems, steam air heaters play a crucial role in providing efficient and reliable heat transfer. These innovative devices are designed to maximize heat exchange between steam and air, ensuring optimal temperature control in various industrial processes.How our steam air heat exchangers work

The temperatures and stresses involved in Factory processes can be extreme and need to be managed strictly. Large Factory steam air heaters are generally made of two or further sections. These may include 'steam', 'condensate', and the elective' flash' sections. As the steam heats the air, it cools down, condenses, and turns to water. The heater configuration not only in counterflow so that cold air entering is the condensate section, but also brought up to temperature in the steam section.