VARAD PROCESS EQUIPMENT AND SYSTEMS

PNEUMATIC CONVEYING SYSTEMS MANUFACTURERS

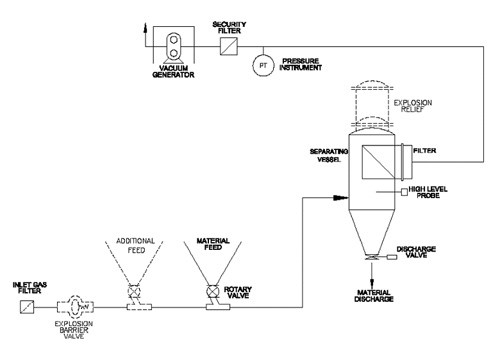

Pneumatic conveying systems are innovative solutions designed to efficiently transport bulk materials through pipelines using air or gas as the conveying medium. This technology plays a crucial role in various industries, including manufacturing, food processing, pharmaceuticals, and mining. Let's delve into the key components and advantages of pneumatic conveying systems. We are leading in Pneumatic Conveying System Manufacturers, Suppliers, Providers and Exporters in India. We are providing the best quality services.