VARAD PROCESS EQUIPMENT AND SYSTEMS

SPIN FLASH DRYER MANUFACTURERS

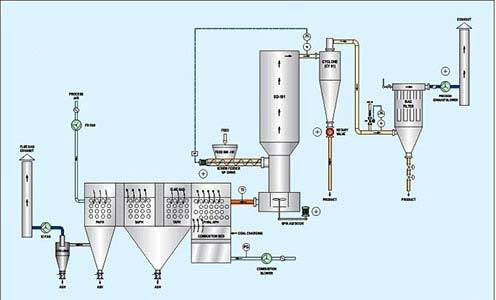

There are the most practical constant drying systems of consistent and non-consistent filter pressing cakes, this type of dryer can handle moisture content up to 20 - 70. As a direct drying process, stuff are brought into contact of hot and dried air. This system made by Varad Process Equipment and Systems offers the advantages of veritably low labor and administration costs

We are leading in Spin Flash Dryer Manufacturers, Suppliers and Providers. we are not just manufacturers; we are architects of drying precision. Our seasoned engineers meticulously design Spin Flash Dryers, ensuring each unit reflects a harmonious blend of efficiency, reliability, and adaptability. Stay ahead of the curve with Spin Flash Dryers, where cutting-edge technology meets practical application. Our units are equipped with the latest advancements, ensuring optimal performance, precise controls, and real-time monitoring capabilities. Our Spin Flash Dryers are not just efficient; they are crafted with environmental responsibility in mind. Experience energy-efficient operation and reduced environmental impact, contributing to both operational efficiency and conservation.